Vacuum technology is an essential field of science and engineering that impacts industries ranging from manufacturing and healthcare to aerospace and electronics. This advanced technology involves creating and maintaining a vacuum environment, enabling numerous processes and innovations that are pivotal in today’s world.

What is Vacuum Technology?

Vacuum technology refers to the generation, measurement, and application of vacuum conditions. A vacuum is defined as a space devoid of matter, including air, and is typically measured in terms of pressure. Achieving these conditions requires specialized equipment such as vacuum pumps, gauges, and chambers.

The absence of air or other particles in a vacuum environment facilitates processes that would otherwise be impossible or inefficient under normal atmospheric conditions.

How Vacuum Technology Works

Creating a vacuum involves removing air and other gases from a sealed space. This is accomplished using vacuum pumps, which operate on principles like:

Positive Displacement: Mechanically trapping and ejecting air from a chamber.

Momentum Transfer: Using high-speed jets or rotating mechanisms to push particles out.

Entrapment: Cooling surfaces or chemical absorption to capture gas molecules.

Once the desired vacuum level is achieved, gauges monitor and maintain the pressure to ensure stability during operations.

Applications of Vacuum Technology

1. Semiconductor and Electronics Manufacturing

Vacuum technology is indispensable in the production of semiconductors, a cornerstone of modern electronics. It ensures a controlled environment free from contaminants, enabling processes like:

Thin-film deposition for microchips.

Etching and patterning in circuit boards.

Manufacturing high-precision components like transistors.

2. Aerospace Industry

In aerospace, vacuum technology simulates outer-space conditions, allowing engineers to test satellites, spacecraft, and components. Thermal vacuum chambers replicate the extreme conditions of space, ensuring equipment reliability and safety.

3. Healthcare and Medical Applications

Sterilization of medical instruments often relies on vacuum systems. Autoclaves use vacuum technology to remove air and ensure the effective penetration of sterilizing agents like steam. Additionally, vacuum packaging is used to preserve pharmaceuticals.

4. Research and Development

Vacuum environments are essential in scientific research. High-vacuum systems are employed in particle accelerators, electron microscopes, and spectroscopy tools, enabling breakthroughs in physics, chemistry, and materials science.

5. Food and Packaging

Vacuum technology is widely used in food preservation. Vacuum-sealing extends the shelf life of products by removing air, which slows down oxidation and microbial growth.

6. Energy and Environmental Applications

Solar panel manufacturing and energy-efficient coatings rely on vacuum processes. Moreover, vacuum distillation helps in separating pollutants from water, contributing to cleaner environments.

Benefits of Vacuum Technology

1. Precision and Accuracy

Vacuum environments eliminate contaminants, ensuring precise and reliable results, especially in sensitive industries like semiconductors and medicine.

2. Efficiency

Processes like coating, welding, and drying are faster and more efficient in a vacuum environment.

3. Enhanced Product Quality

By minimizing exposure to air, vacuum technology improves the durability and performance of manufactured products.

4. Sustainability

Vacuum-based systems often consume less energy and reduce waste, contributing to more sustainable industrial practices.

Challenges in Vacuum Technology

1. Cost of Equipment

Vacuum systems, especially those required for high or ultra-high vacuum conditions, can be expensive to design, install, and maintain.

2. Complexity of Operation

Achieving and maintaining vacuum conditions requires expertise and precise control, which can be challenging for untrained personnel.

3. Material Limitations

Materials used in vacuum systems must withstand high stress and extreme conditions, limiting design choices and increasing costs.

4. Energy Consumption

While vacuum systems improve efficiency, certain applications, like space simulation, can require significant energy resources.

Innovations in Vacuum Technology

Vacuum technology is continuously evolving, driven by advancements in materials science, electronics, and automation. Some of the latest innovations include:

Nano-scale Vacuum Coatings

These coatings enhance the performance of electronics, medical devices, and optical components by improving surface properties.

Green Vacuum System

Eco-friendly designs aim to reduce energy consumption and emissions, aligning with global sustainability goals.

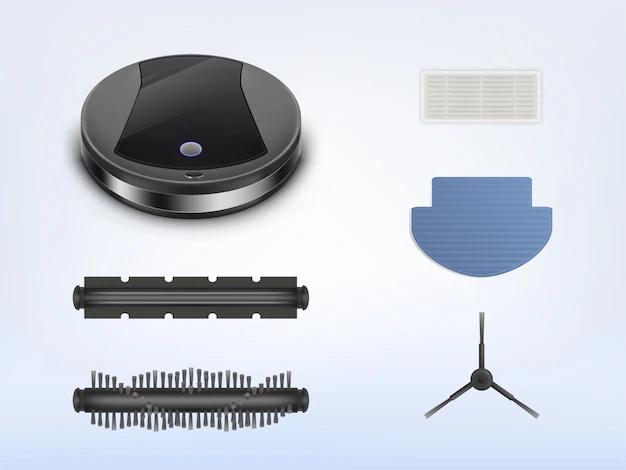

Vacuum Robots

Robotics integrated with vacuum systems are enhancing efficiency in semiconductor manufacturing and other automated processes.

Portable Vacuum Equipment

Compact and lightweight vacuum systems are being developed for field applications, making the technology accessible in remote or challenging environments.

The Future of Vacuum Technology

As industries push the boundaries of innovation, vacuum technology will play a pivotal role in enabling groundbreaking developments. Key areas to watch include:

Quantum Computing

Vacuum systems will be critical in creating stable environments for quantum processors.

Space Exploration

Advanced vacuum chambers will support the testing and development of new spacecraft and exploration equipment.

Medical Advancements

Innovative vacuum-based sterilization and diagnostic tools will revolutionize healthcare delivery.

Energy Storage

Vacuum technology could contribute to developing more efficient batteries and fuel cells.

How to Leverage Vacuum Technology for Your Business

Businesses looking to adopt vacuum technology should consider:

1. Identifying the Right Applications

Evaluate how vacuum systems can enhance your processes, whether in manufacturing, packaging, or research.

2. Investing in Quality Equipment

Choose reliable vacuum pumps, chambers, and gauges to ensure long-term performance.

3. Partnering with Experts

Consult with specialists to design and implement customized vacuum solutions tailored to your needs.

4. Training Employees

Provide training on operating and maintaining vacuum systems to maximize efficiency and safety.

Conclusion

Vacuum technology is an invisible yet indispensable force shaping the modern world. From enabling cutting-edge scientific research to improving everyday products, it has become a cornerstone of progress across industries. By understanding its potential, challenges, and future directions, businesses and individuals can harness this technology to innovate and thrive in an increasingly competitive landscape.

Vacuum technology not only drives efficiency and precision but also opens doors to possibilities once thought to be beyond reach. Whether you’re in manufacturing, healthcare, or research, embracing this transformative technology is a step toward a more advanced and sustainable future.